Etusivu / Kaikki tuotteet / Tuote

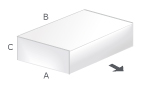

Etipack Pharma Seal has been especially designed to meet the requirements of tamper-evident labelling within operating pharmaceutical packaging lines, by applying two tamper-evident seal labels on formed boxes.

This labelling system has an extremely reduced bulk for a quick and easy installation an integration with other machinery.

Pharma Seal belongs to the Etipack Pharma line, especially dedicated to labelling, coding, serialization and track and trace of pharmaceuticals; this line has been designed to ensure high standards of quality, safety, productivity and maintenance complying with the guidelines for good manufacturing practice of pharmaceutical markets.

The Etipack Pharma line includes different labelling machines, labelling systems and friction feeders to handle a variety of products: ampoules, vials, boxes, syringes, single-dose, inhalers, Blow Fill Seal, inspection and inserting of information notices.

Kun konetta huolletaan säännöllisesti, voidaan viat ennaltaehkäistä. Tilanteissa, joissa on ensiarvoisen tärkeää ehkäistä tuotantokatkokset ja maksimoida koneen käyttöikä, suosittelemme ratkaisuksi huoltosopimusta, joka lisää koneen turvallisuutta ja käyttövuosia.

Huollamme edustamiemme päämiesten laitteistoja – riippumatta siitä, että onko ne alunperin ostettu Cortexilta.

Y-tunnus: 1800277-6

poinvoices@cortex.fi

laskutus@cortex.fi

Valitettavasti emme pysty ottamaan vastaan verkkolaskuja.